Fittings

At Karaki Tategu Joinery, we offer a wide range of fittings, from elegant wooden pieces to sturdy steel designs, crafted with precision and care. Whether you’re seeking the warmth of traditional Japanese woodwork or the strength of modern metal fittings, we have something for every space.

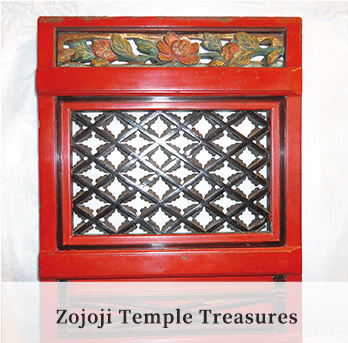

Traditional Japanese shoji with lattice top, glass center, and solid wood base at high-end restaurants

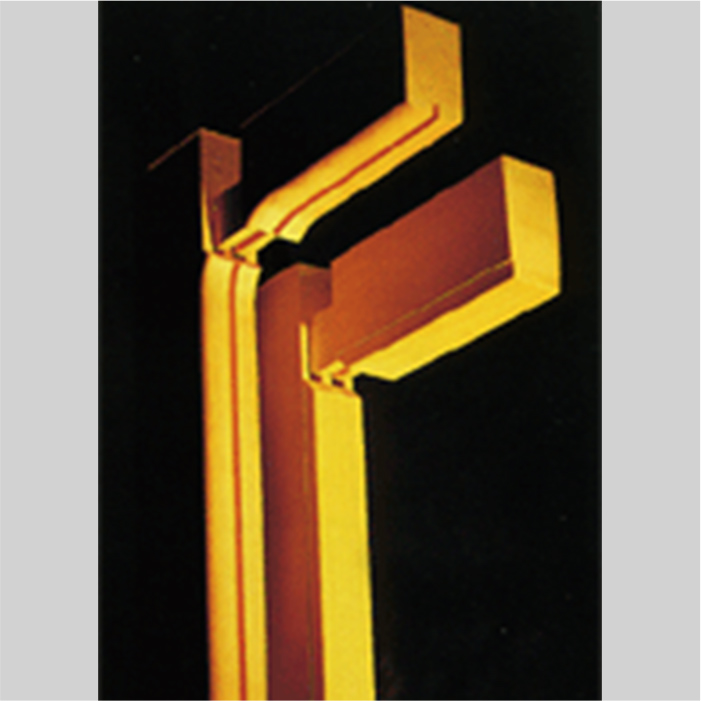

Sheath for traditional storehouse door

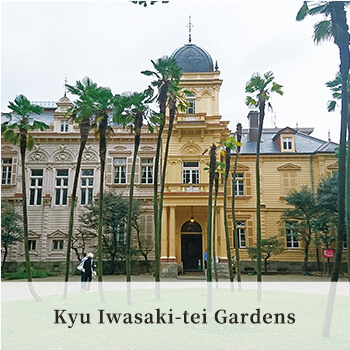

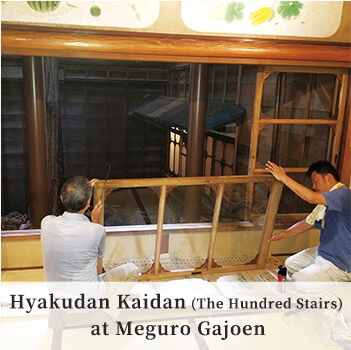

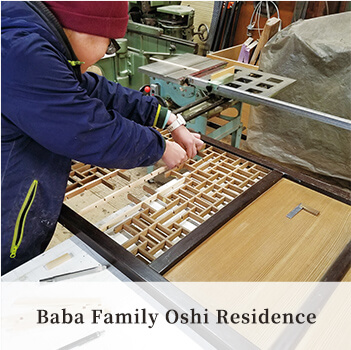

Cultural Properties, Temples, Shrines, and Treasures

We also specialize in creating and restoring fittings for cultural properties, temples, and shrines, using rare designs and techniques that are not often seen in public. If you’re interested in these unique projects, we’d be happy to hear from you.

Explore the Art of Joinery

Types of Wooden Joinery

Shoji Screen

Yoshino Cedar "Akami" (reddish tint)

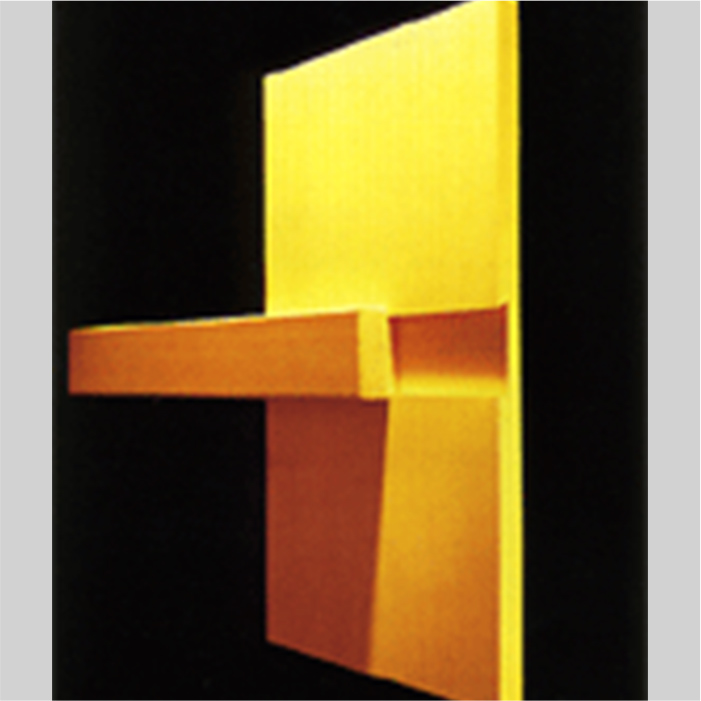

Entrance Door

Yoshino Cedar "Akami"

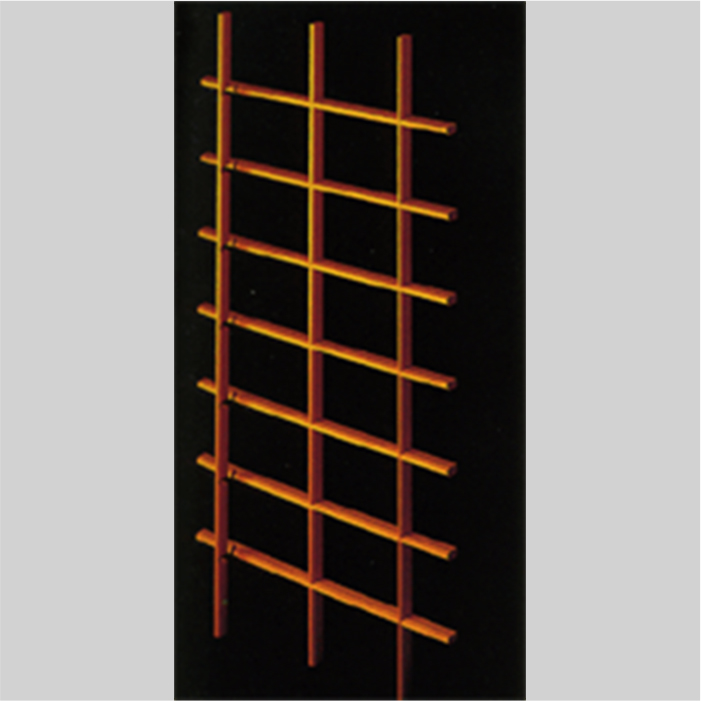

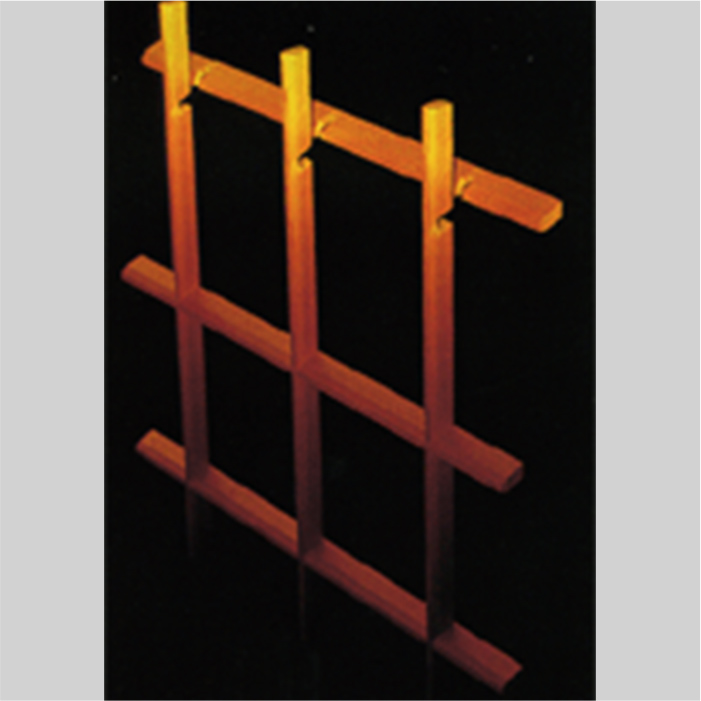

Lattice Door

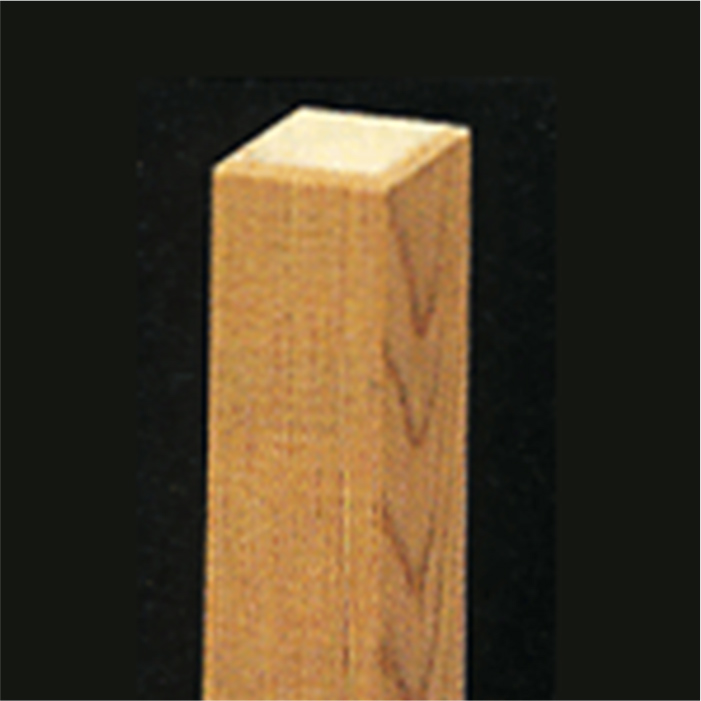

American Douglas Fir

Glass Door

Yoshino Cedar "Akami"

Board Door

Yoshino Cedar "Akami"

Flush Door

Cedar with plain-sliced veneer

Fusuma (Sliding Door)

Tea Room "Taiko Fusuma" (drum-style sliding door)

Kumiko Joinery Door

Kiso Cypress "Akami"

Design Door

Yoshino Cedar "Akami"

Popular Types of Wooden Joinery Materials

Akita Cedar (Red)

The red hue comes from the intermediate section between the heartwood and the outer white sapwood.

The grain is straight and fine, with a glossy, smooth texture, making it ideal for detailed craftsmanship.

<Top-grade joinery material>

Akita Cedar (Red and White Mix)

This material comes from the sapwood of the log, blending red and white hues.

The grain is straight and soft, making it easy to work with.

Kiso Hinoki (Red, also called Bishu Hinoki)

Pale yellow in color with excellent durability.

Its fine grain gives an elegant, refined, and clean appearance.

<Top-grade joinery material>

Kiso Hinoki (Red and White Mix)

This material comes from the sapwood of the log, blending red and white hues.

The grain is mostly straight, with minimal warping.

Ezo Spruce

Pale yellow in color, relatively light and soft but strong.

Easy to process and finish.

Tamo (Ash)

Ochre in color with straight grain and a coarse texture. Strong and flexible, suitable for both interior and exterior use.

Keyaki (Zelkova)

Reddish-brown to whitish-brown in color, with a dense grain and lustrous surface. Very strong and suitable for both interior and exterior use.

<Top-grade joinery material>

Spruce

Pale yellow in color, with uniform texture and no odor. Lightweight and easy to work with, ideal for all types of wooden joinery.

Noble Fir

Light brown in color, with fine grain that is resistant to sun-fading. Medium hardness.

Douglas Fir

Comes in reddish, yellow, and white varieties. A widely used imported wood with a beautiful grain similar to red pine.

Western Hemlock

Pale yellow in color, with a fine texture, hardness, and elasticity. It is resistant to rot, easy to work with, and highly durable.

Western Red Cedar

Reddish in color, known for its excellent durability and weather resistance. Light and soft, but prone to splitting.

Cloud Spruce (AK Spruce)

Yellow-brown in color, with a fine texture similar to spruce.

Teak

Brownish in color with a rich, smooth texture. Highly water-resistant and, despite its hardness, easy to work with.

The Journey of Crafting Wooden Joinery-From Concept to Completion

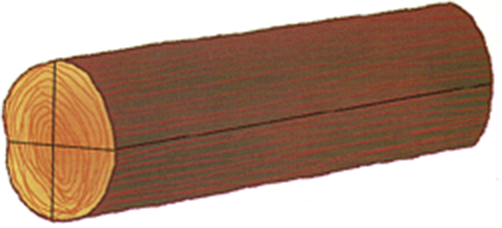

Log

A tree that has been felled, with its branches removed. The reddish part of the wood, known for its strength and durability, is primarily used in joinery.

Quarter-sawn Lumber

For logs larger than 30cm in diameter, the log is first quartered, and each section is sawn as shown in the diagram, in one direction at a time.

Flat-sawn Lumber

For joinery materials, it is essential that there are no knots or defects. Any dead knots, resin pockets, or reaction wood are removed.

Artificial Drying or Natural Drying

Artificial Drying:

Two methods are used: steam drying and combustion gas drying. The drying process can be controlled freely and completed in 7 to 101 days. However, it requires high equipment costs, and the loss rate of the wood is a disadvantage.Natural Drying:

By considering ventilation and location, the wood is either stacked horizontally (with spacers) or leaned vertically to dry. Although a large quantity of wood can be dried with good color and gloss, the drying process is time-consuming, and reducing the moisture content below the air-dry level is difficult.

Lumber Cutting

Once dried, the flat-sawn lumber is efficiently cut into parts for joinery, taking into consideration the grain and color of the wood.

Final Product

By carefully selecting wood based on its quality, color, and grain, durability and a beautiful finish are ensured. Only 39% of the log is utilized as joinery material. For superior joinery, the selection of materials and craftsmanship are of utmost importance.Wood Joinery Techniques

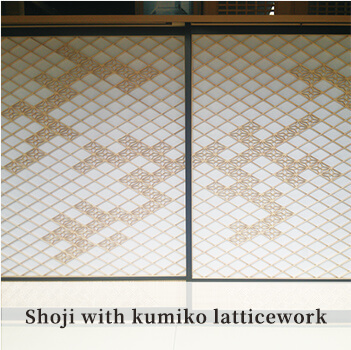

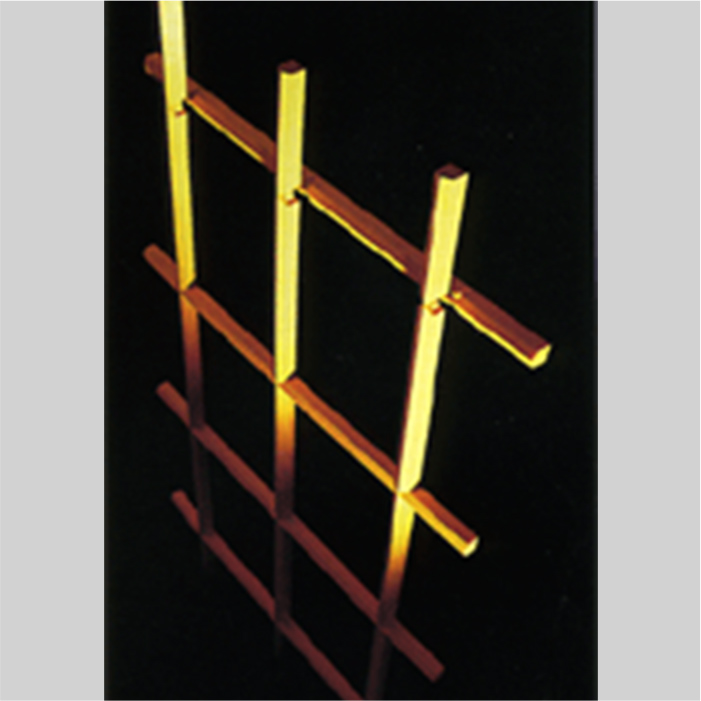

Chamfered Kumiko

The joints where the vertical and horizontal kumiko (wooden lattice pieces) meet are called "kumite."

"Chamfered Kumiko" refers to kumiko that has been chamfered (beveled) to create a luxurious finish. This requires advanced skill to perfectly align the chamfered edges at the joints.

Chamfered Dust Guard Kumiko

Known as "dust guard" or "dust drop," this technique involves creating a slope (approximately 20-30°) on the horizontal kumiko of shoji screens. This is truly a display of craftsmanship, and only a few artisans today are capable of mastering this technique.

Rounded and Chamfered Tenon Joints (Koshikata)

"Rounded" refers to shaping two parts so they form a curve when joined. The chamfered surfaces, which have stepped edges, must be perfectly aligned at a 45° angle, requiring skill. The place where the vertical and horizontal pieces meet is called the "dozuki," and one method of finishing this is called "koshikata." This technique not only looks beautiful but also resists temperature and humidity changes, preventing gaps from forming over time.

Dovetail Joints (Ari Hozo and Ari Mizo)

For doors, high-end board doors, and other joinery where nails or screws would detract from the appearance, a dovetail joint technique is used, known as "cutting the dovetail."

By adding slight variations in width (by millimeters) to the dovetail groove, the joint fits perfectly, eliminating gaps. Once fitted, the joint is sturdy and aesthetically clean.

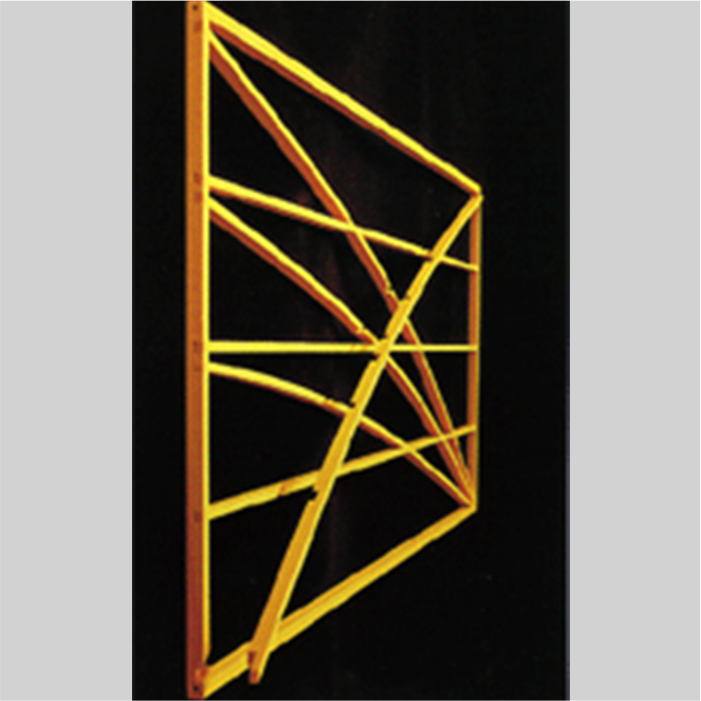

Curved Kumiko

Commonly referred to as "curved work," this technique involves assembling kumiko into curved shapes.

It is primarily used for decorative purposes in shoji screens, Shoin-style shoji, and ceiling lattices.

Softwoods like hinoki (Japanese cypress), hiba (Japanese arborvitae), and spruce, which are easy to bend, are ideal for this technique.

Fine-toothed "dozuki saws" are used to cut the joints at an angle that matches the curve.

The "single-handed joint method" is employed, where the kumiko are assembled in one direction.

Tokin Joint

"Tokin" refers to the shape of the surface, specifically a pentagonal, mountain-like form. The term comes from the headdress worn by Yamabushi (mountain ascetic monks). The "Tokin Joint" involves using the Tokin surface for both the vertical and horizontal kumiko.

This highly precise and advanced technique is the pinnacle of joinery craftsmanship and can be considered the crowning achievement of master artisans.